Uninterruptible Power Systems for Diagnostic and Treatment Facilities

Flywheel System

This year at the 54th ASHE Annual Conference & Technical Exhibition in Indianapolis, Indiana, two of JPT’s team members, Sean Kozielec, P.E. and Brent Spangler, presented a lecture on how a flywheel system serves as a beneficial alternative to uninterruptible power sources (UPS) for diagnostic and treatment facilities using imaging equipment.

A flywheel is essentially a rotating disc that spins at an unbelievably high RPM. This spinning disc is contained in a vacuum enclosure to reduce resistance and is used to convert kinetic energy to produce direct current power.

Typically, the most popular choice of technology for a UPS source are stand-alone battery backup systems using valve regulated lead acid (VRLA) batteries. In many instances, a UPS of 150KVA or greater is required for each piece of imaging equipment. Eventually, a hospital ends up with many of these UPS units which all require floor space close to the imaging equipment, cooling and humidity control, periodic testing and maintenance. These requirements lead to increased maintenance and operation costs and more floor space allocation.

A centralized and modular flywheel system requires lower maintenance, less floor space and lower environmental impact when compared to batteries. Cooling and humidification systems that serve the UPS rooms can be consolidated generating a positive impact on maintenance, operation and reliability.

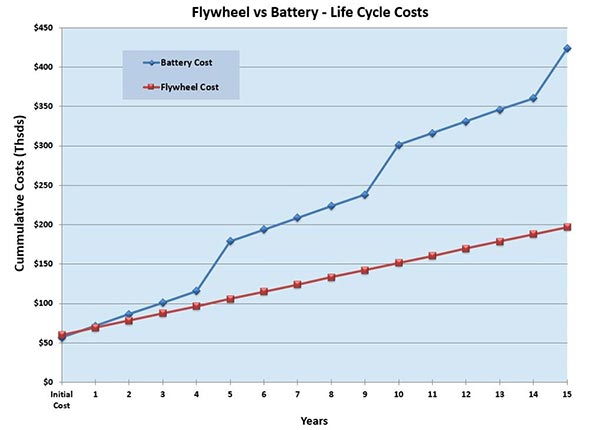

There is some apprehension associated with flywheel systems due to the initial 30% to 40% cost increase in comparison to batteries, but there is a payback of five years or less when all aspects of the installation are considered. Additionally, there is concern in flywheel technology when comparing the short duration of back-up power. Typically, battery UPS systems are sized to support power requirements for 10 to 15 minutes while flywheels are sized to provide 15 seconds of back-up power. However, power quality studies indicate the majority of utility power disturbances last for less than five seconds and sound design practices of fuel fired power generation systems last for less than ten seconds.

Applying proper design techniques, a centralized flywheel based UPS back-up power system can reduce facility life cycle costs, maintenance requirements, and the amount of hazardous materials stored within a hospital. Implementation of a modular design can further reduce initial costs and allow a facility to convert their existing UPS back-up power to flywheel technology over time.

Please check out the slideshow below!